Recently, researchers at the Massachusetts Institute of Technology (MIT) developed an ultra-thin lightweight photovoltaic cell, which can generate 18 times as much electricity per kilogram as traditional photovoltaic panels, and can be easily deployed to the surface of various objects.

It is reported that the flexible and durable photovoltaic cells are much thinner than hair. They can adhere to strong and lightweight fabrics, and can easily stick to the surface of fixed objects. They can provide power as a wearable fabric, and can also be transported and rapidly deployed in remote areas, and can provide power in emergencies. Its weight is one percent of that of traditional photovoltaic panels, its power generation per kilogram is 18 times that of traditional photovoltaic panels, and it can be produced in large scale through printing process using semiconductor ink.

Because these photovoltaic cells are very thin and light, they can be pasted on the surface of many different objects. For example, they can be attached to the sails to provide power for their navigation at sea; It can be adhered to tents and tarpaulins for disaster recovery and rescue; Or it can be applied to the wing of UAV to expand the flight distance. Of course, this lightweight photovoltaic cell can also be easily installed on the building surface.

Vladimir Bulovi, Chairman of Fariborz Maseeh Emerging Technology and Director of the Organic and Nanostructure Electronics Laboratory (ONE Laboratory) at MIT ć In his published paper on this technology, he said, «The technical indicators used to evaluate new photovoltaic cells are usually limited to energy conversion efficiency and unit cost. It is also important that they can be integrated, that is, the adaptability of new technologies. Light photovoltaic fabrics can be integrated, and can be installed on almost any object. In view of the urgent need to deploy renewable energy at present, we are committed to accelerating the adoption of photovoltaic systems.»

With Bulovi ć The paper was also published by Mayuran Saravanapavanantham, a graduate student in electrical engineering and computer science at MIT, and Jeremiah Mwaura, a research scientist at the Electronic Research Laboratory at MIT.

Thinner and thinner photovoltaic cells

Traditional crystalline silicon photovoltaic cells are fragile, so they must be packaged with thick glass and aluminum frames, but this form limits their deployment location and method.

The research team of ONE Lab used an emerging thin film material to produce photovoltaic cells six years ago, which is very light and can even be placed on soap bubbles. However, these ultra-thin photovoltaic cells are manufactured by a complex vacuum process, which is expensive, so it is difficult to realize large-scale production.

In the research, they began to develop printable thin film photovoltaic cells based on semiconductor ink and scalable manufacturing technology.

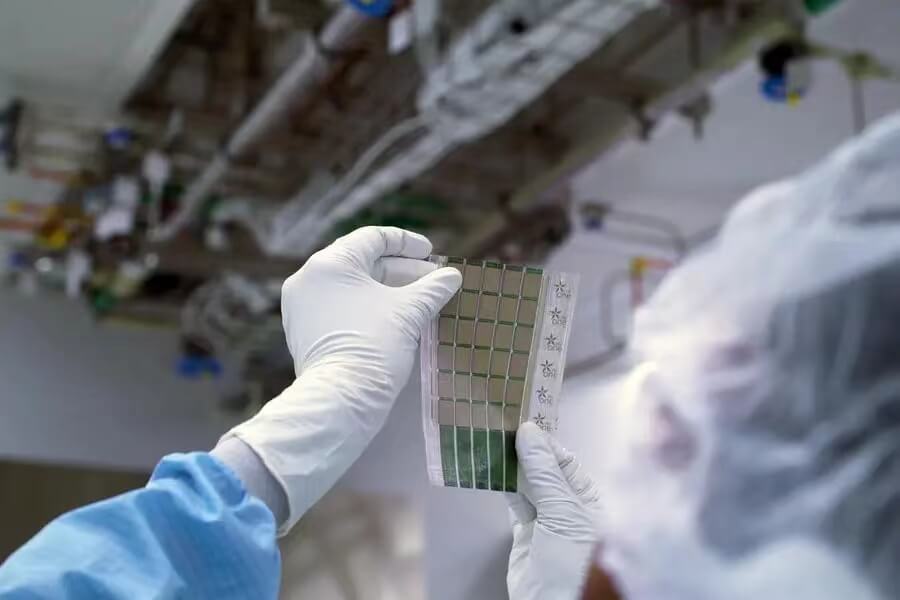

To produce this kind of photovoltaic cell, researchers used a kind of printable nanometer material. They used a slot coating machine to coat the photovoltaic cell structure in the MIT nano-clean room. This coating machine deposited the electronic material layer onto the prepared releasable substrate, which is only 3 microns thick. Then, electrodes are deposited on the structure through the screen printing process (a technology similar to adding patterns to T-shirts) to build photovoltaic modules.

Researchers can then peel the printing module about 15 microns thick from the plastic substrate to form an ultra-light photovoltaic module. However, this ultra-thin photovoltaic module is difficult to handle and easy to tear, which will make it difficult to deploy. In order to solve this problem, the research team of MIT has found a lightweight, flexible and high-strength substrate that can attach photovoltaic cells to the substrate, and fabric is the best solution, because they provide mechanical flexibility and flexibility, and hardly add weight.

They found an ideal composite material, which weighs only 13 grams per square meter, and its commercial name is Dyneema. This kind of fabric is made of very strong fiber, which is even used as a rope for salvaging sunken ships. By adding a layer of UV curing adhesive with a thickness of only a few microns, researchers can adhere photovoltaic modules to this fabric, thus forming an ultra-light and solid photovoltaic structure.

Saravanapavanantantham explained: «Although it seems easier to print photovoltaic cells directly on the fabric, this will limit the choice of possible fabrics or other receiving surfaces. In order to make it compatible with all processing steps required for manufacturing equipment in chemical and thermal aspects, our method separates the manufacturing of photovoltaic cells from the final integration.»

Beyond traditional photovoltaic cells

When testing this new photovoltaic cell, researchers found that when it was deployed independently, it could generate 730W of electricity per kilogram; If it is deployed on the high-strength Dyneema fabric, it can generate 370W of electricity per kilogram, and its power generation is 18 times that of traditional photovoltaic panels.

Saravanapavanantantham said, «A typical rooftop photovoltaic system in Massachusetts has a power of about 8kW. In order to generate the same amount of electricity, the ultra-thin photovoltaic cells we installed on the roof only increase the weight of 20kg.» He said that the researchers also tested the durability of the photovoltaic cells and found that even if they rolled and unfolded more than 500 times, they still retained more than 90% of the power generation capacity.

Although the ultra-thin photovoltaic cells developed by them are much lighter and more flexible than the traditional photovoltaic cells, another material is needed to protect the photovoltaic cells from the impact of the environment. The carbon-based organic materials used to manufacture ultra-thin photovoltaic cells may degrade by interacting with water and oxygen in the air, which may reduce their performance.

Mwaura said, «Of course, like traditional photovoltaic cells, ultra-thin photovoltaic cells can also be packaged in glass, but this will significantly reduce the value of such photovoltaic cells. Therefore, our research team is currently developing ultra-thin packaging solutions, which will only slightly increase the weight of ultra-light photovoltaic cells. We are trying to remove non-photovoltaic active materials, while still maintaining the shape coefficient and performance of these ultra-light and flexible photovoltaic structures 。 For example, we know that printing the transferable substrate can further simplify the manufacturing process, which is equivalent to the process of manufacturing other layers in our equipment. This method will accelerate the transformation of this technology to the market. «

In addition, it is reported that this research was supported by the MIT Energy Program, the National Science Foundation of the United States and the Natural Science and Engineering Research Council of Canada.